Crane Kits vs Fully Assembled Overhead Cranes in Indonesia

Indonesia's industrial sectors are expanding rapidly, increasing the demand for reliable overhead crane solutions. This section introduces key factors driving crane use and compares procurement options. Indonesia's industrial sectors—from steel fabrication workshops in Bekasi to mining operations in Kalimantan and port facilities across Java—rely heavily on overhead cranes for safe and efficient material handling. The rise in industrial activity has increased the need for cost-effective and reliable overhead crane solutions tailored to local conditions. Choosing the right type of crane goes beyond price. Factors such as installation time, local workforce skills, and long-term maintenance are critical. This guide helps plant managers, engineers, and procurement officers decide which approach best suits their operational needs, budget, and site conditions. Crane Kits: Fully Assembled Cranes: This section highlights the industrial demand for overhead and bridge cranes, local supply capabilities, and regulatory factors affecting crane deployment in Indonesia. Indonesia's industrial growth has created steady demand for overhead cranes and bridge cranes across multiple sectors: Duty classes vary from light to heavy, with steel mills and ports using higher-duty cranes for continuous operations. Indonesia's industrial base is supported by local fabrication and service providers. Many buyers prefer crane kits when local capabilities are strong, enabling on-site assembly and customization: This network reduces downtime and allows flexible crane configurations, particularly when using crane kits. Buyers must account for regulations and logistics when deploying cranes in Indonesia: These factors influence whether buyers choose crane kits for local assembly or fully assembled overhead cranes. This section explains what crane kits are, their advantages, challenges, and ideal use cases in Indonesia. overhead bridge crane kit for sale Indonesia A crane kit is a set of components supplied for local assembly, allowing companies to build a customized overhead crane or overhead bridge crane on-site. This approach provides flexibility in design while reducing transportation challenges compared to shipping fully assembled cranes. Using a crane kit offers several benefits for industrial buyers in Indonesia: These factors make crane kits a practical choice where local technical expertise is available. Despite advantages, crane kits come with challenges that buyers must consider: Buyers should weigh these challenges against cost savings before committing to a crane kit. Crane kits are most effective where local expertise and fabrication capabilities exist: In Indonesia, crane kits are popular in steel workshops, medium-sized fabrication plants, and logistics hubs where local assembly is feasible and cost advantages are significant. This section explains what fully assembled cranes are, their advantages, challenges, and ideal use cases in Indonesia. A fully assembled overhead crane is delivered as a complete overhead crane or overhead bridge crane, built and tested at the manufacturer's facility before shipment. Ideal for buyers seeking a plug-and-play solution with predictable performance from day one. Fully assembled cranes offer several practical benefits for industrial buyers with limited local assembly capabilities: These benefits save time, reduce operational risks, and improve efficiency in demanding industrial environments. Despite the advantages, fully assembled cranes have practical considerations: Buyers should weigh these factors when considering fully assembled cranes for Indonesian sites. Fully assembled cranes are best suited where on-site assembly is challenging or precision is critical: In Indonesia, fully assembled cranes are often selected for ports, large steel mills, and logistics hubs where downtime or misalignment can severely impact operations. This section compares crane kits and fully assembled cranes across key factors such as Total Cost of Ownership, performance reliability, project timelines, and local content considerations. When deciding between a crane kit and a fully assembled overhead bridge crane, it's important to consider the total cost of ownership, including: Considering these factors gives a better overall picture of the total cost over the crane's lifecycle. In industries like steel mills, ports, and fabrication workshops, quality and reliability are crucial: Reliability is key for minimizing downtime and ensuring safe operation in industrial settings. Time is critical in crane deployment: Support and local partnerships play a critical role in long-term crane performance: Balancing local involvement with reliable after-sales support is key for Indonesian buyers. This section highlights the unique factors in Indonesia that influence the decision between crane kits and fully assembled cranes, from geographical logistics to workforce capabilities and local regulations. Indonesia's geography—comprising over 17,000 islands—presents logistical challenges for crane transportation. Buyers must plan for inter-island and inland delivery: Regulatory and tariff factors can have a significant impact on crane procurement in Indonesia: Workforce skills and training availability play a major role in determining whether crane kits or fully assembled cranes are the better option: This section provides a structured framework to help industrial buyers in Indonesia decide between crane kits and fully assembled overhead cranes based on their specific needs. Choosing between a crane kit and a fully assembled overhead bridge crane requires careful consideration of several practical factors. Buyers should ask themselves: Answering these questions helps narrow down the most suitable procurement model for your industrial environment. A simple evaluation matrix can help compare overhead cranes and bridge cranes objectively. Key criteria include: Each factor can be scored, allowing buyers to weigh trade-offs and make a more informed decision tailored to their facility. Different types of industrial operations in Indonesia may benefit from different crane procurement approaches: These case studies illustrate how Indonesian industrial buyers have successfully deployed both crane kits and fully assembled cranes to meet their specific operational needs. A medium-sized steel fabrication plant in Bekasi opted for a crane kit to install a 20-ton overhead bridge crane across its assembly hall. Key Details: Outcome: A major port terminal in Surabaya needed a 50-ton overhead crane for container handling and heavy cargo movement. The terminal chose a fully assembled bridge crane due to tight project timelines and limited local assembly resources. Key Details: Outcome: From these case studies, several practical insights emerge for Indonesian industrial buyers: These examples highlight that both crane kits and fully assembled cranes have specific advantages depending on the application, making informed selection crucial for industrial efficiency and safety.Introduction

Industrial Growth and Crane Demand in Indonesia

Why Compare Crane Kits and Fully Assembled Cranes?

Defining the Two Procurement Models

Market Overview: Crane Deployment in Indonesia

Industrial Demand Drivers

Local Supply Chain and Service Capabilities

Regulatory and Infrastructure Considerations

Crane Kits: Features, Benefits, and Challenges

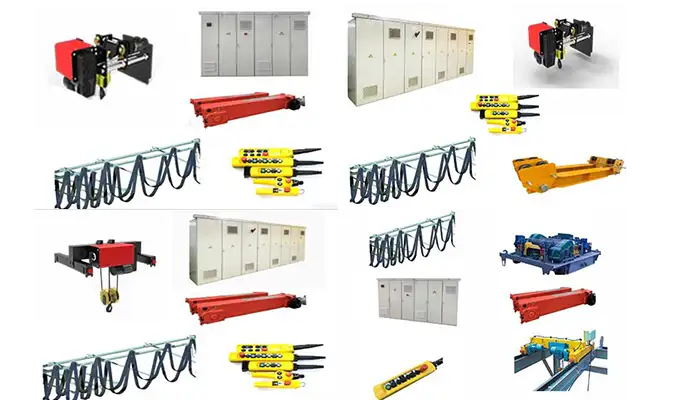

What Constitutes a Crane Kit

Advantages of Crane Kits

Challenges of Crane Kits

Best Use Cases in Indonesia

Fully Assembled Cranes: Features, Benefits, and Challenges

What Defines a Fully Assembled Crane

Advantages of Fully Assembled Cranes

Challenges of Fully Assembled Cranes

Best Use Cases in Indonesia

Comparative Analysis

Total Cost of Ownership (TCO)

Quality and Performance Reliability

Project Delivery Timelines

Local Content and After-Sales Support

Indonesia‑Specific Factors Affecting the Decision

Geographical Fragmentation and Logistics

Local Regulations and Import Tariffs

Workforce Skills and Training Availability

Decision Framework for Buyers

Strategic Procurement Questions

Scoring or Decision Matrix

Practical Recommendations by Buyer Type

Case Studies

Example: Crane Kit Deployment in a Fabrication Plant

Example: Fully Assembled Crane Installation at a Port Facility

Lessons Learned

Conclusion

Summary of Key Insights

Choosing between a crane kit and a fully assembled overhead bridge crane depends on several practical factors:

- Crane kits offer cost savings, flexibility for local modification, and easier shipping, but require skilled on-site assembly and precise project management.

- Fully assembled overhead cranes provide factory-tested quality, faster commissioning, and predictable performance, though they come with higher transportation and import costs.

- Site-specific factors in Indonesia—such as geography, logistics, local workforce skills, and regulatory requirements—play a major role in determining the best procurement model.

- Total Cost of Ownership (TCO), quality, project timelines, and after-sales support must all be evaluated to make an informed decision.

Final Recommendation Tailored to Indonesian Context

For Indonesian industrial operations:

- Large plants with in-house fabrication teams may benefit most from crane kits, especially for custom layouts or variable production needs.

- Ports, steel mills, and facilities with limited assembly resources should consider fully assembled overhead bridge cranes to ensure fast, safe, and reliable operation.

- Always weigh logistical challenges, import duties, and the availability of skilled technicians when selecting a crane model.

By considering these factors, buyers can choose a crane solution that balances cost, efficiency, and long-term reliability.

Next Steps for Prospective Buyers

- Assess technical capabilities: Determine whether your team can assemble and maintain a crane kit or if fully assembled cranes are more practical.

- Evaluate site and logistical constraints: Consider transport routes, available space, and infrastructure.

- Engage with certified crane suppliers: Request detailed quotations, technical support, and references for installation and maintenance services.

- Plan for long-term maintenance: Ensure spare parts availability, warranty coverage, and local service support for overhead cranes and bridge cranes.

Appendices

Reference materials and decision tools for overhead crane procurement

Glossary of Technical Terms

A quick reference for common terms used in overhead crane and bridge crane procurement:

- Overhead Crane: A crane with a hoist traveling along a horizontal beam, commonly used in factories and workshops.

- Bridge Crane / Overhead Bridge Crane: A type of overhead crane where the bridge spans the width of the workspace, supported by runways on both sides.

- Crane Kit: A set of crane components shipped for local assembly on-site.

- Fully Assembled Crane: A crane delivered pre-built and tested at the factory, ready for installation.

- FAT (Factory Acceptance Test): Pre-delivery testing to verify crane performance, alignment, and safety compliance.

- Duty Class: Classification of crane usage intensity, based on load, frequency, and operational conditions.

Sample Cost Comparison Table

A practical framework for comparing crane kits and fully assembled overhead bridge cranes:

| Criteria | Crane Kit | Fully Assembled Crane | Notes |

|---|---|---|---|

| Initial Purchase Cost | Lower | Higher | Depends on manufacturer and capacity |

| Transportation / Shipping | Compact, easier to ship | Larger, higher cost | Consider inter-island logistics in Indonesia |

| Installation Time | Requires skilled on-site team | Minimal on-site work | Fully assembled cranes save assembly time |

| Technical Expertise Needed | High | Low | Kits need trained fitters and engineers |

| Quality & Reliability | Depends on assembly quality | Factory-tested, predictable | Factory testing reduces alignment errors |

| Flexibility for Modifications | High | Limited | Kits can adapt to local plant layout |

| Warranty / Support | Standard | Often enhanced | Fully assembled cranes may offer better coverage |

Checklist for Evaluating Crane Procurement Options

Use this checklist to make informed decisions when selecting overhead cranes, bridge cranes, or overhead bridge cranes in Indonesia:

- Define maximum load and lifting height requirements.

- Determine span, runway length, and workspace layout.

- Assess technical capabilities for on-site assembly.

- Evaluate transport and logistical feasibility for fully assembled units.

- Compare total cost of ownership (TCO) including installation, maintenance, and spare parts.

- Check compliance with Indonesian industrial standards and safety regulations.

- Confirm warranty terms, after-sales support, and availability of local service providers.

- Consider potential for future expansion or modifications.